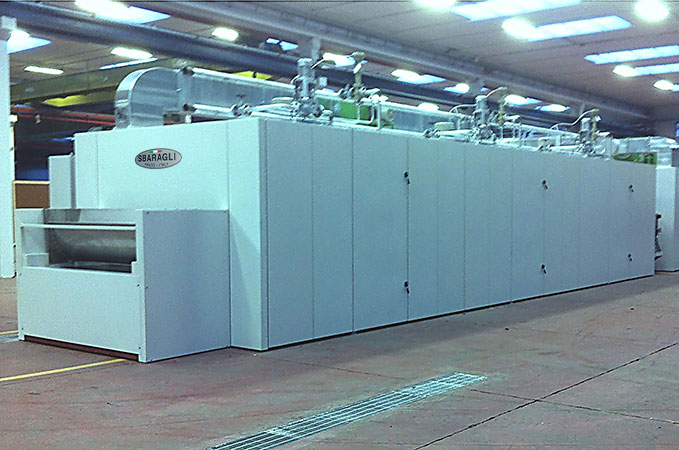

OVEN

Type TP/S

The oven TP/S is designed for the thermosetting of tows of synthetic fibres (PP - POLYESTER - POLYETHYLENE - ETC. ) . two separate units, one for hot and one for cold, process are the innovation of this machine, and make it different from the traditional thermo-setting ovens. In fact, in the traditional ovens there was a single conveyor belt that from the hot zone entered the cold one. With this cooling system the results were poor since the cooling air, in addition to the material, also had to cool the conveyor belt that had accumulated heat. In the oven TP/S, instead, the hot zone is completely separated from the cold one. In fact, there are two independent conveyor belts provided with their own drive. The material, after having covered the entire length of the hot zone, is unloaded onto the second belt of the cold zone. With this system the material undergoes high thermic shock with the conseguent perfect setting. The bearing structure is made of steel sections and coldpressed sheets. The haet insulation is obtained with panelling realized for for perfect heat sealing. Thanks to the modularity of the zones, the oven TP/S may have various dimensions. Length of each zone: mm 2500 or 3300 - The working length may vary according to the client's requests ( mm 1300 - 2000 - 2500 - 3000 ). A fan, connected to a motor located on the upper part of the machine, forces the air that, after having crossed the heating batteries, is conveyed to a diffusion zone and is distribuited uniformly on the material and then collected, filtered and put into circulation again. The humid air is ejected to the outside through adjustable throttle valves located on the upper part of the machine. The conveyor belts may also be made with nets or stainless steel slats mounted on roller chains. The cooling zone is provided with a special widemesh net coveyor belt in order to enable minimum air resistance. The drive of the belts may be realized with inverters - hydraulic converters. The possibility exists to vary the speed of the belts with a potentiometer installed on the elettric board. The heating batteries may be foreseen with operation by means of diathermic oil - steam - electric power - gas.

"LOADER (FALDATORE) FOR TOW"

Horizontal Loader with ribbon of transport and movement of linear

Characteristics:

- Ribbon of transport in silicone, motorized with motoreducer operated by inverter, power HP. 1,5.

- Least speed 15 metri/mins.

- Maximum speed 130 metri/mins.

- Width ribbon mm.600 (modifiable to application)

- Length ribbon mm.1870 (modifiable to application)

- Horizontal position, earth height mm.1200 with more regulation + 100 less 100.(to application possibility of construction also tilted in slope or in descent.)

- Movement gotten through linear guides with muffs spheres slide, motorized with reduction gear and motor Brushless from 11,77 N/ms. (varying according to the greatness of the loader)

- Maximum run mm.1400 (adjustable) to get a stratum of mm.2000 Obtainable wisecracks at the most of the speed 16 toward Dx and 16 toward Sx to the minute ( speed of the translation 45 meters lineari/ms. )